For Temperature Monitoring Systems (RTD)

What is the CMI Module for Temperature Monitoring Systems (RTD)?

It is a Centralized, PLC / PC / Web based solution, designed to provide maintenance and operations personnel at industrial sites with continuous access to critical, real-time RTD probe temperature information. This module helps identify and resolve temperature related equipment issues before process interruptions occur, exorbitant premature repair costs are incurred, safety parameters are exceeded, or catastrophic failures occur.

It is a Centralized, PLC / PC / Web based solution, designed to provide maintenance and operations personnel at industrial sites with continuous access to critical, real-time RTD probe temperature information. This module helps identify and resolve temperature related equipment issues before process interruptions occur, exorbitant premature repair costs are incurred, safety parameters are exceeded, or catastrophic failures occur.

What It Does

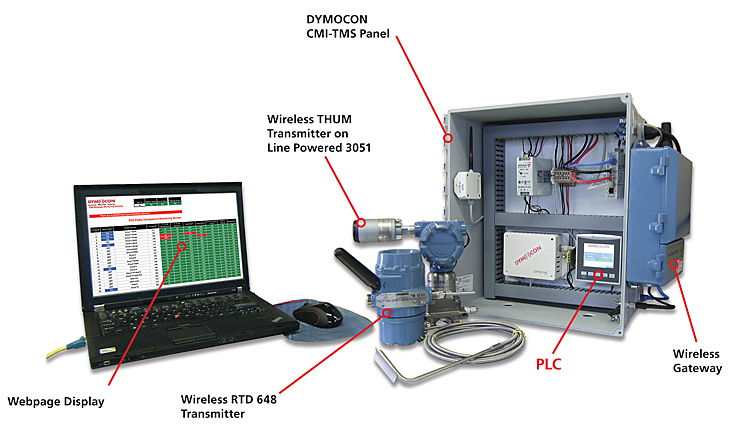

The CMI (Control, Monitor, Inform) Module for RTD Temperature Monitoring Systems can monitor up to 60 RTD probes. The probes can either be wired directly to the Module Panel, or can be wired to a wireless transceiver communicating with a gateway in the Module Panel. Wireless transceivers (based on IEEE 802.15.4) transfer information at 1 to 15 minute intervals, and help avoiding data transport noise issues commonly found on wires. All logged information is saved by the PLC on an SD card and exported every 6 hours to a PC or server as an Excel and .csv file for trending analysis, documentation, and analysis of equipment operation.

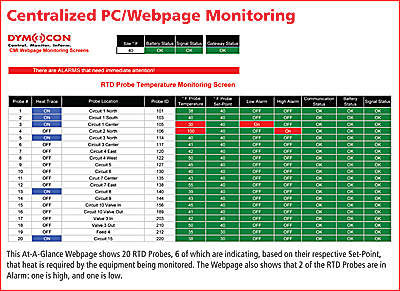

The CMI-TMS Module delivers all monitoring information in real-time through a PC browser based Webpage (shown above), delivered by the PLC over an Ethernet connection. All operating temperature status information is shown with corresponding alarms. A “Remote Operator Utility” in the CMI Module, allows PC users to directly access the PLC, to acknowledge active alarms, and to access detailed alarm information and resolution hints.

How It Works

The CMI Module for RTD Temperature Monitoring Systems (CMI-TMS) uses a baseline of user defined set-point values for temperature, to provide a Low Alarm or High Alarm when RTD probe readings are below or above expected temperature parameters. With this information, operators can confirm that heat trace circuits are operating as expected to protect equipment from freezing, and heat trace lines from damage from high equipment operating temperatures. Operating RTD Probe temperature data and alarms are synthesized into a PC accessible webpage (see over), for an “at-a-glance” view of equipment status. Stored logs can be accessed by a browser-based analysis tool to generate information listings, reports, and trend graphs.

CMI Modules provide 2 connections for PC access to the PLC for monitoring and control, and one connection for the user’s Web server to provide browser-based access to the monitoring Webpage. A fourth connection is reserved by DYMOCON for service and support of the TMS Module, Browser-Based Analysis Tool, and off-site backup of logged data. The CMI-TMS module is delivered installed at the site as a fully integrated solution. All CMI Modules are a wireless and / or wired management solution that will enhance industrial systems and help lower plant operating costs, capital expenditures, and lost / down time, while improving risk management and productivity.

Download a PDF about the CMI MODULE TMS [1.72 MB]

Copyright © 2024

Copyright © 2024